Linear Actuators: Types, Applications, and Advantages

Linear actuators play a pivotal role across various industries, serving as the silent workforce behind countless processes. They are mechanical devices responsible for converting energy into controlled motion or force, driving the machinery that keeps our world in motion. Linear actuators are essential components in sectors as diverse as manufacturing, logistics, and automation. This article takes a closer look at the three primary methods through which linear actuators operate: hydraulics, pneumatics, and electricity.

Pneumatic Actuators

Pneumatic actuators feature a straightforward design comprising a piston inside a hollow cylinder. The piston's movement within the cylinder is driven by pressurized air supplied by a manual pump or external compressor. This pressure propels the cylinder along the piston's axis, generating the linear force required for various applications. Upon completion, the piston returns to its original retracted position, either through spring-back force or the supply of fluid to the opposite side.

Advantages of Pneumatic Actuators

-

Simplicity: Pneumatic actuators are known for their simplicity, offering a cost-effective solution for high-force and high-speed applications.

-

Temperature Resistance: They can withstand a wide temperature range, making them suitable for diverse environments.

-

Safety: Pneumatic actuators are inherently safe, as they do not use hazardous materials or magnetic interference, meeting explosion protection and machine safety requirements.

-

Cost-Effectiveness: These actuators are lightweight, durable, and cost less than their hydraulic and electric counterparts. They also require minimal maintenance.

Disadvantages of Pneumatic Actuators

-

Pressure Loss and Air Compressibility: Pneumatic systems are less efficient due to pressure losses and air compressibility, resulting in reduced forces and speeds.

-

Specific Sizing: Pneumatic actuators need precise sizing for efficient operation and often require proportional regulators and valves, increasing complexity and cost.

-

Air Contamination: Contamination by oil or lubrication in the air can lead to downtime and maintenance issues, necessitating clean and humidity-controlled air.

Hydraulic Actuators

Hydraulic linear actuators share similarities with pneumatic actuators but utilize incompressible hydraulic fluid supplied by a pump instead of pressurized air. These actuators are renowned for their ability to excel in high-force applications, making them ideal for heavy-duty tasks.

Advantages of Hydraulic Actuators

-

High Force: Hydraulic actuators can generate substantial forces, often surpassing those of pneumatic cylinders.

-

Incompressibility: Hydraulic fluids allow for force and torque to remain constant without additional fluid or pressure, thanks to incompressibility.

-

Flexible Footprint: Pumps and motors can be placed at a distance from actuators with minimal power loss.

Disadvantages of Hydraulic Actuators

-

Fluid Leaks: Hydraulic systems are prone to leaks, leading to efficiency loss and potential damage to surrounding components.

-

Complexity: Hydraulic actuators require numerous components, resulting in intricate linear motion subsystems. Operator involvement is significant, including setup, monitoring, and maintenance.

-

Efficiency: Hydraulic actuators typically operate in the 40%-55% efficiency range and can be noisy.

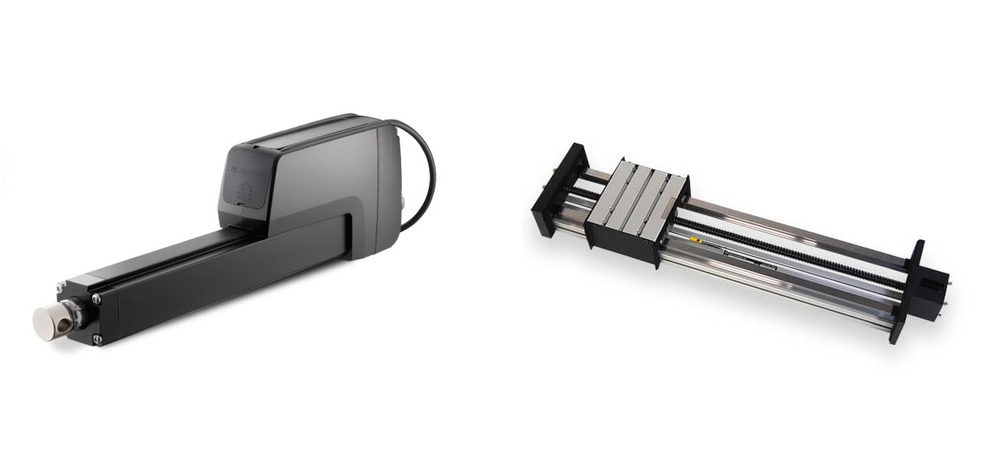

Electric Actuators

An electric actuator serves as a mechanism to transform rotary motion into linear movement, enabling the lifting, lowering, sliding, or tilting of objects and machinery. These actuators offer a reliable and environmentally friendly means of motion control that is both efficient and low-maintenance. Electric linear actuators rely on either a DC or AC motor, equipped with a set of gears and a lead screw, to propel the primary rod shaft forward or backward.

Advantages of Electric Actuators

-

Accuracy and Repeatability: Electric actuators provide precise control with high accuracy and repeatability.

-

Programmability: They can be networked and reprogrammed for customized motion profiles, offering versatility.

-

Quiet Operation: Electric actuators are quieter than pneumatic and hydraulic systems.

-

Clean and Safe: They do not involve hazardous fluids and are suitable for various environments.

-

Efficiency: Electric actuators operate with high efficiency, and their total cost of ownership is often lower due to minimal maintenance.

Disadvantages of Electric Actuators

-

Initial Cost: Electric actuators may have a higher initial investment compared to other types.

-

Environmental Limitations: Not all environments are suitable for electric actuation, and velocity limitations may apply.

-

Overheating: Continuous operation may lead to overheating, potentially impacting performance.

Applications of Linear Actuators

Linear actuators find application in various industries due to their versatility and precise control. Some common applications include:

Industrial Automation

In industrial automation, linear actuators are used for tasks such as conveyor belt control, robotic arm movement, and precise positioning of equipment. They enable efficient and accurate automation processes, enhancing productivity and reducing manual labor.

Robotics

Linear actuators play a crucial role in robotics, enabling precise movement and control of robotic arms, grippers, and joints. They allow robots to perform complex tasks with high accuracy, making them invaluable in manufacturing, healthcare, and research.

Medical and Healthcare

Linear actuators are used in medical equipment such as hospital beds, dental chairs, and surgical tables. They provide smooth and controlled movement, ensuring patient comfort and precise positioning during medical procedures.

Automotive

In the automotive industry, linear actuators are utilized in various applications, including adjustable seats, headrests, sunroofs, and trunk opening mechanisms. They enhance comfort and convenience for vehicle occupants while enabling automated functions.

Home Automation

Linear actuators are incorporated into home automation systems to control window blinds, door locks, and adjustable furniture. They allow homeowners to automate various aspects of their homes, providing convenience and customization.

Conclusion

In conclusion, the choice between pneumatic, hydraulic, and electric linear actuators depends on specific project requirements. Each type comes with its own set of advantages and disadvantages, and careful consideration is essential to select the right actuator for the task at hand. As technology continues to evolve, linear actuators will remain a cornerstone of industrial innovation, driving progress and efficiency in diverse sectors.

HVH Industrial Solutions is an authorized distributor of AirTAC, Thomson, and Macron Dynamics and we offer a wide range of their linear actuators. We work closely with their engineering team to provide superior customer service and engineering support.

If you have any questions, write to us via live chat, call, or send us a quote request. The HVH team is always ready to help you.