Formsprag Backstopping Clutches: Ensuring Safety and Reliability on the Mount Washington Cog Railway

Introduction

The Mount Washington Cog Railway in New Hampshire has been an iconic attraction, ferrying visitors to the highest peak in the Northeastern United States for over a century. Operating under extreme weather conditions and steep gradients, the railway required a reliable and robust braking system to ensure passenger safety and prevent roll-back on the treacherous mountain slopes. In 2001, the railway turned to Formsprag backstopping clutches, a solution that not only addressed their concerns but also provided long-lasting performance and peace of mind.

About the Mount Washington Cog Railway

The Mount Washington Cog Railway, established in 1869, boasts a remarkable history of transporting passengers to the summit of Mount Washington, standing at an elevation of 6,288 ft. above sea level. With wind chill temperatures plunging to -102ºF and record-breaking surface wind speeds of 231 mph, the railway endures some of the most extreme weather conditions on the planet. The railway's fleet includes a combination of steam and biodiesel locomotives, along with seven passenger coaches.

Challenges with the Ratchet-Pawl System

Prior to 2001, the passenger coaches relied on a ratchet-pawl system for emergency stops and preventing roll-back. However, this system posed several challenges. Passengers often complained about the constant "dinging" noise caused by the ratchet system throughout the entire journey. Moreover, the ratchet mechanism proved unreliable for sudden emergency stops, leading to potential damage to various components of the coaches. An alternative solution was imperative to enhance passenger comfort and safety.

Using the Formsprag Backstopping Clutch System

To address these concerns, Al Laprade, a consulting mechanical engineer and former railway employee, designed a unique sprag clutch system in 2001. This system, developed exclusively for passenger coaches, replaced the outdated ratchet-pawl mechanism. The Formsprag FSO clutches were chosen for their exceptional engineering, comprehensive testing, and proven reliability. Caleb Gross, a Mechanical Engineer at the railway, highlighted Formsprag's extensive engineering information, thorough testing, and honesty as pivotal factors in their decision.

Al Laprade discovered the reliability and effectiveness of Formsprag clutches during a visit to Bretton Woods, a nearby ski area owned by the same company that operated the Cog Railway. A Formsprag clutch installed on a chairlift carousel demonstrated exceptional performance. This success, coupled with Formsprag's reputation and engineering expertise, made them the clear choice for the railway's needs. The selected Model FSO 800 clutches featured high torque capacity (13,000 lb.ft.) and rugged construction, ensuring their suitability for the challenging mountain terrain.

The Formsprag clutches installed on the passenger coaches of the Mount Washington Cog Railway have demonstrated exceptional longevity and reliability. Caleb Gross stated that since the installation of the first clutch in 2001, there has been no reason to consider replacement. Regular field testing confirms the effectiveness of the clutches, ensuring that the coaches remain in position during stops and preventing backward movement downhill.

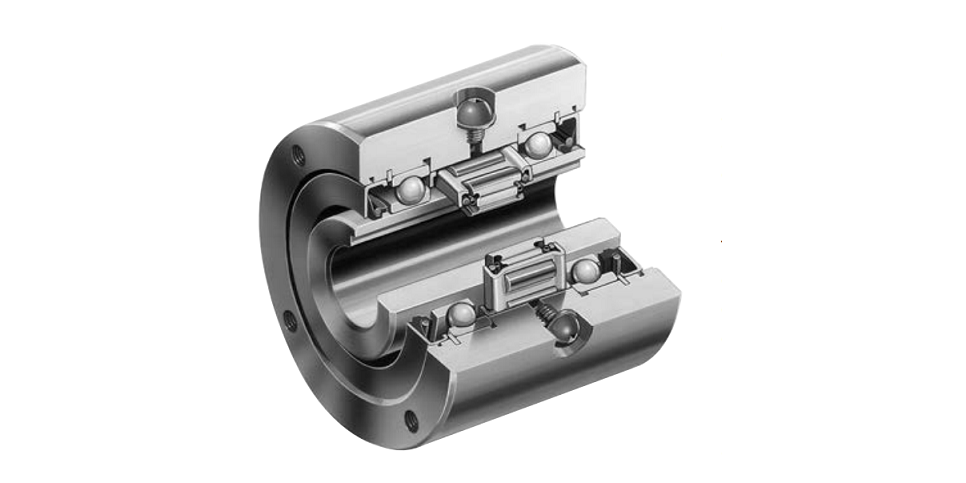

Formsprag FSO Clutch Design

The Formsprag FSO clutches, equipped with PCE sprags featuring Formchrome and Formsprag "Free-action" retainers, provided the necessary torque capacity and durability required for the application. With a compact 10-inch diameter, these clutches seamlessly integrated into the existing hardware and limited space within the older coaches. The clutches were grease-lubricated with lip seals, specifically chosen to prevent lubricating oil leakage onto the adjacent caliper brake rotors, thus maintaining optimal braking performance.

One critically important feature of the sprag clutch system is its ability to prevent rollback on the mountain slopes. A backstopping sprag clutch is installed on the down-mountain axle of each coach, engaged by the brakeman during the up-mountain portion of the trip. Hydraulic calipers hold the clutch rotor stationary, and flipping a valve applies hydraulic pressure, preventing the sprag rotor from rotating. This configuration ensures a safe ascent without the risk of rollback. For the descent, the clutch is disengaged to allow downward movement, further enhancing safety and control.

Conclusion

The implementation of Formsprag backstopping clutches on the Mount Washington Cog Railway has greatly enhanced passenger safety, addressed previous concerns, and provided reliable performance in the face of extreme weather conditions and steep gradients. These clutches have proven their mettle, offering the railway peace of mind and the assurance of a smooth, comfortable journey for visitors to the breathtaking summit of Mount Washington.

HVH Industrial Solutions is an authorized distributor of Formsprag Clutch and we offer a wide range of their clutches and clutch couplings. We work closely with their engineering team to provide superior customer service and engineering support.

If you have any questions, write to us via live chat or call or send us a quote request. The HVH team is always ready to help you.