What are Overload Release Clutches

What are Overload Release Clutches

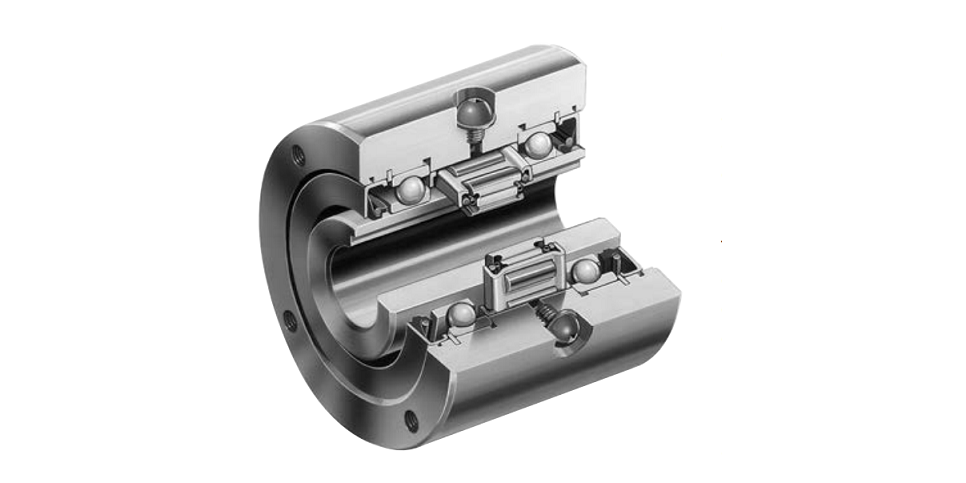

Overload release clutches are industrial clutches that have an added functionality: automatic disengagement when a predetermined torque threshold is reached. Once this preset torque level is reached, an internal cam mechanism triggers the complete disengagement of the clutch, resulting in the cessation of power or torque transmission.

Post-disengagement, these industrial clutches necessitate manual re-engagement before resuming power transmission. Additionally, these clutches can be engineered to establish rotational positioning (indexing) between two rotating bodies. In indexing applications, the re-engagement point can be defined in degrees, ensuring synchronization with driven devices at critical timing intervals.

Overload Release Clutches vs. Torque Limiters

|

Type |

Operation |

Reset |

Feature |

|

Torque Limiter |

Continuous |

Automatic |

Maintains constant torque level |

|

Overload Release |

Safety Stop |

Manual |

Fully disengages when overload limit reached |

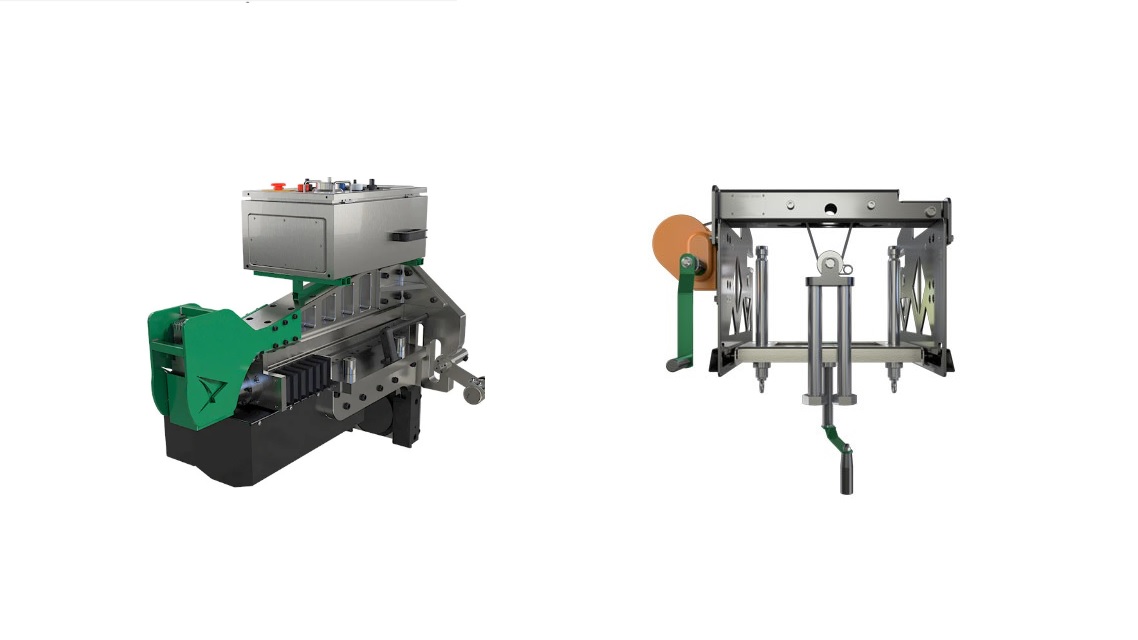

The selection of the appropriate device depends on the specific application and the characteristics of both the driving and driven components. Take, for instance, a scenario involving a conveyor propelled by an electric motor. When a jam or obstruction occurs, preventing the conveyor's movement, the use of a torque limiter can pose a safety risk to the personnel operating the system. In such cases, if the obstruction is manually cleared, the torque necessary to restart the conveyor is reduced immediately. The motor, which remains engaged with the conveyor even during a slip condition, promptly resumes movement, potentially causing harm to personnel still addressing the jam.

In instances where a torque limiter is used for power transmission, the design engineer must acknowledge the existence of 'stored energy' in the system when the driving element is activated, even if the driven device remains stationary. Consideration of safety factors becomes essential in such environments.

On the other hand, overload-release industrial clutches offer a distinct advantage in the example of the conveyor. These clutches ensure a complete disengagement of the conveyor and prevent its restart until the jam is cleared. Operating personnel must then clear the area, perform a positive reset of the clutch, and allow the conveyor to resume operation, enhancing safety measures.

Torque limiters find their utility in applications where the driven device cannot handle the full output torque generated by the driving element. Consider an electric motor driving a bottle-capping machine as an example. Sufficient torque is required to twist the cap into position, but when the cap fits tightly onto the bottle, additional torque could result in damage to the product, the capper, or both. In this scenario, the torque limiter ensures a snug fit of the cap without applying excessive torque, guaranteeing efficient operation with minimal downtime in the capping process.

Conclusion

As we weigh the advantages against torque limiters, it's clear that overload-release clutches provide a strategic pause in power transmission, ensuring a safer operational environment and minimizing potential risks during interruptions. Whether it's preventing accidents with automatic disengagement or allowing controlled resets, overload release clutches prove to be indispensable for fostering a secure and efficient workplace.

HVH Industrial Solutions is an authorized distributor of Carlyle Johnson, Ringspann, Rexnord, Warner Electric, Inertia Dynamics, Ringfeder, Formsprag, Mayr, Dalton Gear, and Bibby Turboflex, and we offer a wide range of their clutches. We work closely with their engineering team to provide superior customer service and engineering support.

If you have any questions, write to us via live chat or call or send us a quote request. The HVH team is always ready to help you.