Installation and Removal Procedure of Ringfeder Smart-Lock

Image source https://www.ringfeder.com

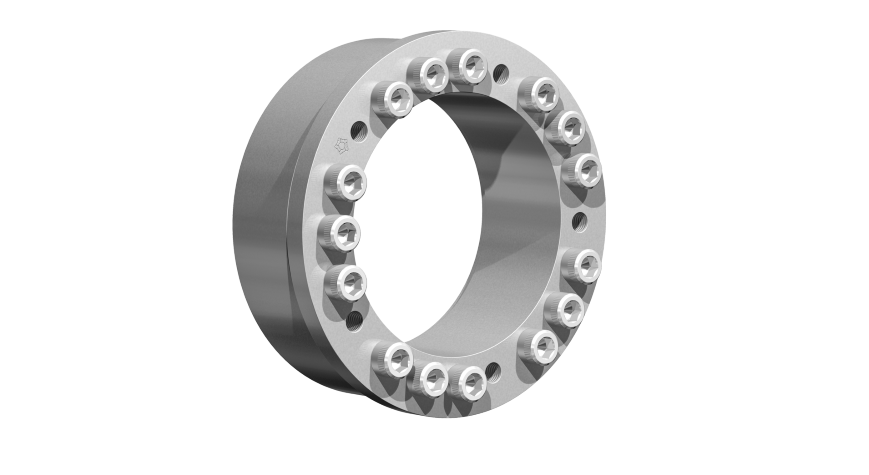

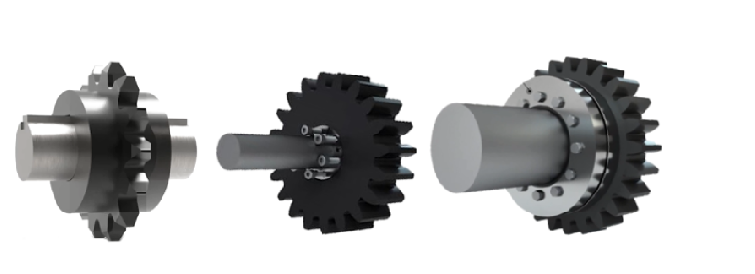

Ringfeder Smart-Lock is an economic gearbox shaft connection consisting of cylindrical bushings and a Shrink Disc locking device. The bushings are made with the solid shaft’s outside diameter and the inside diameter of the hollow shaft. The Shrink Disc locks all components together using a series of tapered thrust rings that create a mechanical interference fit between the Smart-Lock bushings and the shafts. It is a device that:

-

Cuts Inventory Costs

Smart-Lock’s standard adaptor bushings work with hollow shafts from 44mm to 90mm—so a given gearbox can now support a wide range of solid shaft sizes without changing the shaft or shrink disc. This interchangeability can reduce gearbox spare parts inventory costs by 70%.

-

Saves Installation Time

Thanks to the Shrink Disc coupling and the simplicity of the adaptor bushings, Smart-Lock is accessible to both install and remove. It takes only a few minutes to install in most applications, and it can be disassembled just as quickly.

-

Reduces Manufacturing Costs

Before Smart-Lock, solid shaft outside diameters and hollow shaft inside diameters needed to be precision machined to exact dimensional tolerances and finishes, Smart-Lock compensates for clearances up to 0.2mm, eliminating the need for expensive precision machining operations and allows the use of low-cost solid shafting materials.

-

Provides a Reliable Torque Transmission

Smart-Lock doesn’t skimp on reliability or power transmission for all its simplicity and cost-saving potential. Transmissible torque on standard Smart-Lock systems ranges from 580 to 5,600 Nm.

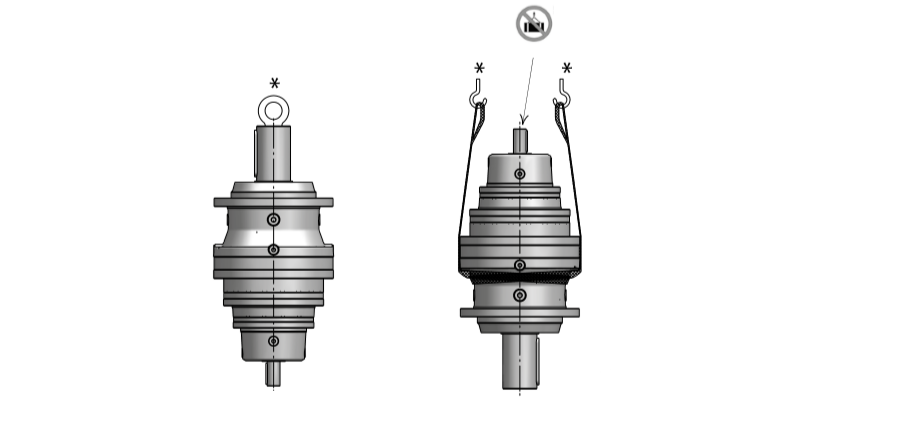

Installation

-

Check all parts for dimensional accuracy. The hollow shaft OD should have a tolerance of h8. The maximum clearance between the shaft OD and hollow shaft ID is 0.007 inches (0.2 millimeters).

-

Clean up the hollow shaft OD and shaft ID. They should be clean and dry, without oil and grease.

-

Check the surface finish on the shaft and hollow shaft. The finish should be between 32 and 125 RMS.

-

Place the support bushing on the hollow shaft. It is necessary to add the light oil to the support bushing only to assist with insertion.

Shrink Disc Tightening Procedure

- Tighten the screw in a circular pattern

- Use quarter-turn increments

- Repeat circular tightening passes

- Stop when each screw reaches full torque

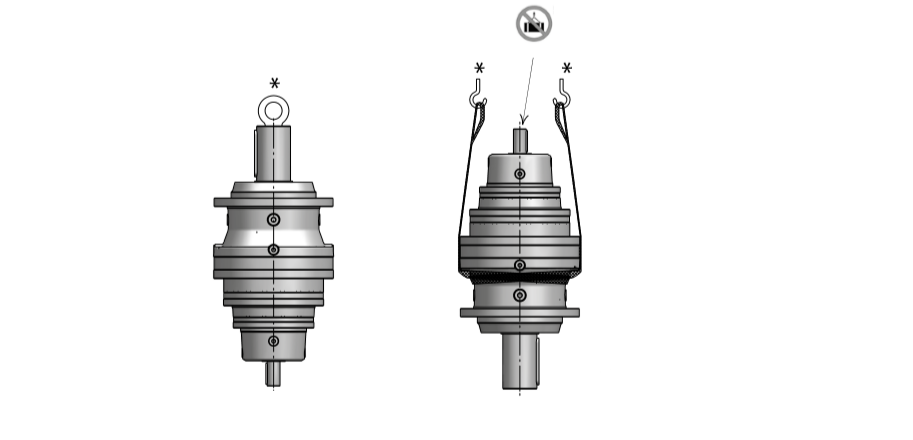

Correct Installation

Removal

-

Release each screw of the shrink disk gradually, use a circular pattern and work in quarter-turn increments.

-

Loosen the support bushing screw.

-

Remove the shrink disc. First, verify that the Shrink Disc is free, remove the shaft or pull the hub from the shaft.

RF-Smart-Lock-Installation-Removal

Also, have a look at our post Keyless Locking Assemblies for Your Specific Application.

Feel free to Contact Us if you have any questions, need more information or if you are interested in purchasing a smart lock.

HVH Industrial Solutions is an authorized distributor of Ringfeder. We work closely with their engineering team to provide superior customer service and engineering support.

Vladimir Harutyunyan

Vladimir Harutyunyan is the founder of HVH Industrial. He has masters degree in mechanical engineering and over 10 years of experience in mechanical power transmission field.

Feel free to connect with Vlad on Linkedin: https://www.linkedin.com/in/vladharut

Vladimir Harutyunyan

Vladimir Harutyunyan is the founder of HVH Industrial ...

Feel free to connect with Vlad on Linkedin: https://www.linkedin.com/in/vladharut