How to Optimize the Performance of Mechanical Drive Trains with GAM

Mechanical drive trains are vital components of motion control systems and are essential in the operation of automated systems and material handling machines, among others. The efficiency of these machines is often dependent on the performance of mechanical drive components. In this article, we will talk about GAM mechanical drive trains and how to optimize the performance of mechanical drive systems.

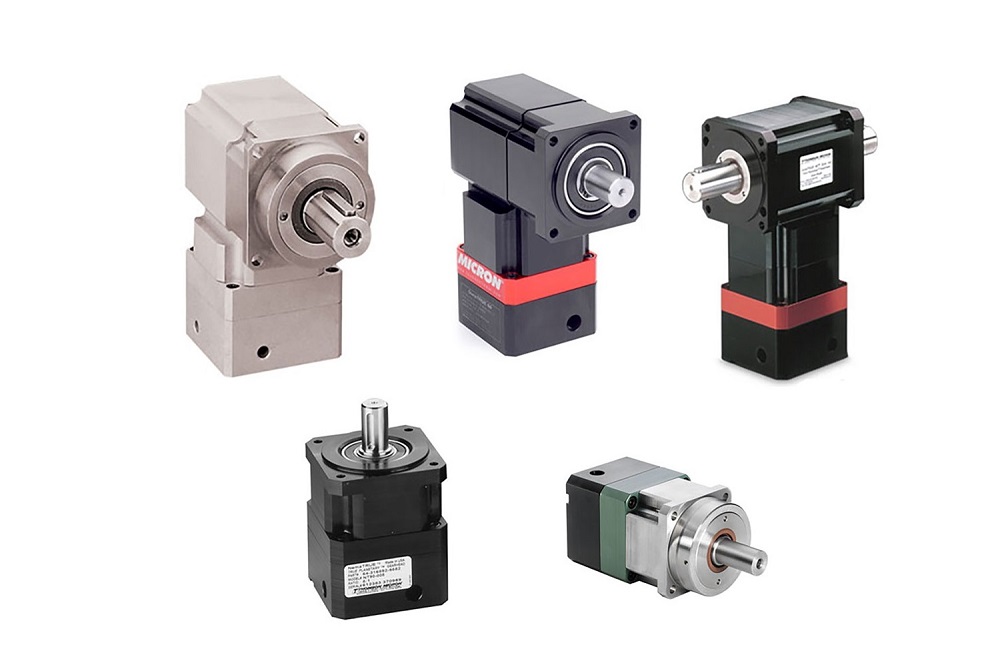

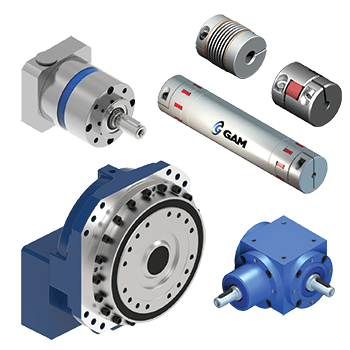

What are GAM Mechanical Drive Trains

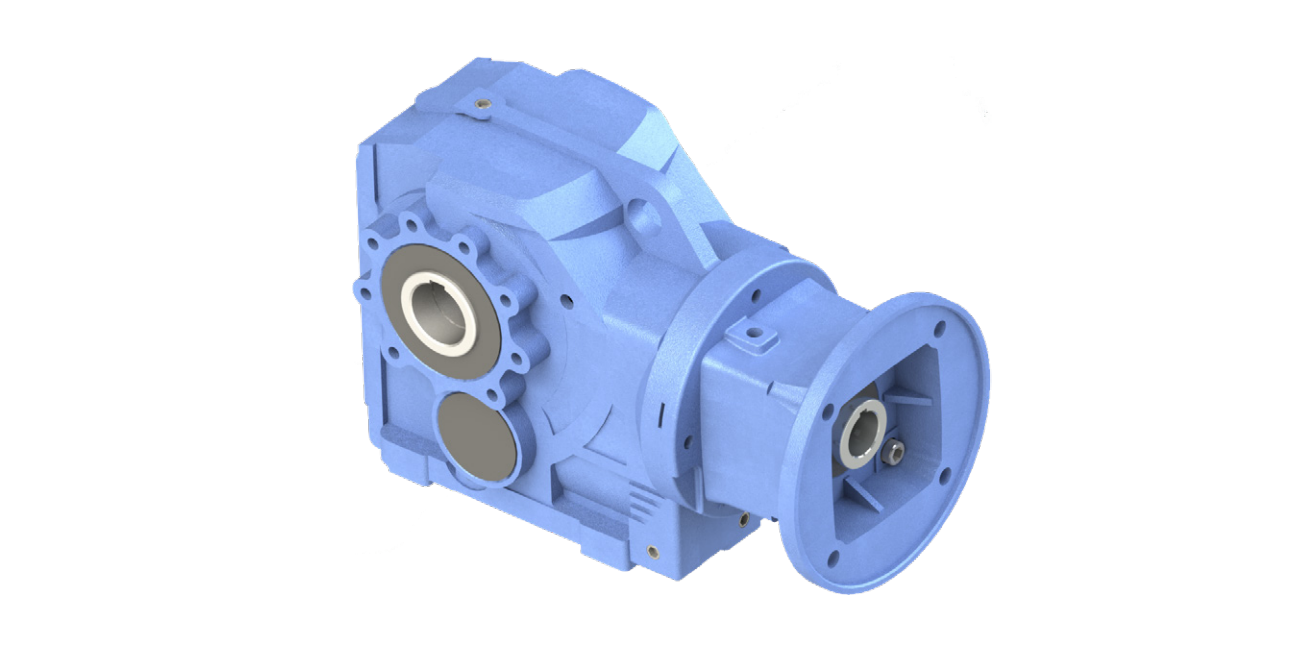

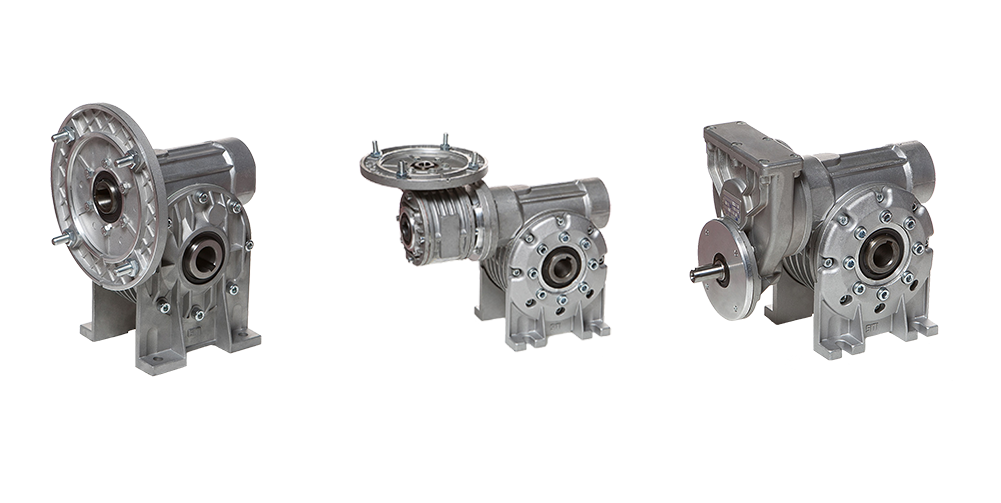

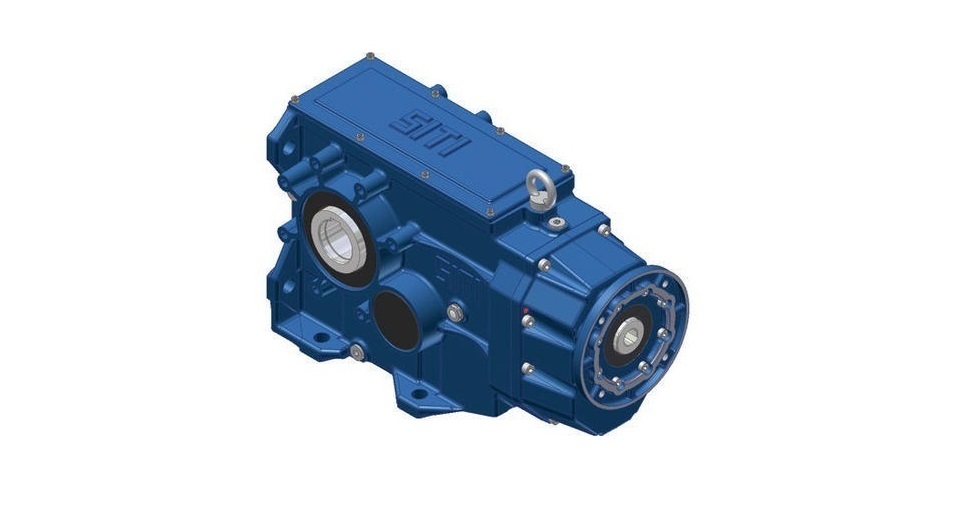

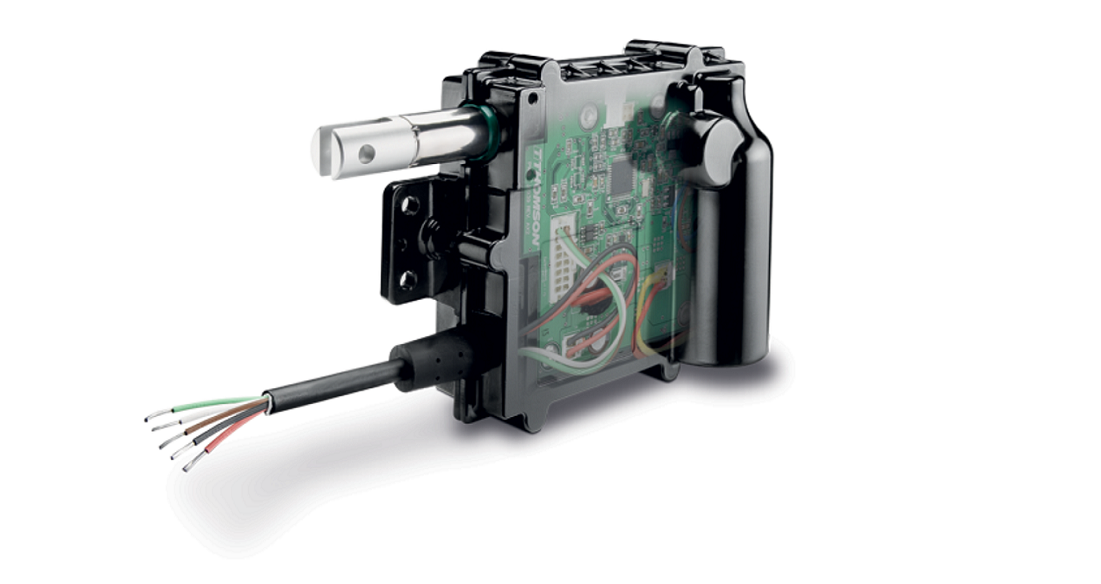

GAM Mechanical drive trains are an essential component of many industrial machines, providing the torque and power necessary to move heavy loads and perform complex tasks. These drive trains consist of a series of interconnected gears, shafts, and other components that work together to transmit power from the motor to the driven load. GAM Mechanical Drive Trains are designed to be durable and reliable, even in harsh environments where other drive trains might fail.

Features and Benefits of GAM Mechanical Drive Trains

GAM Mechanical Drive Trains have several features that make them stand out from other mechanical drive trains in the market. Some of these features and benefits include:

-

Customizable Design: GAM Mechanical Drive Trains can be customized to fit the specific needs of each machinery. This means that they can be designed to match the power requirements, speed, and other specifications of the machine.

-

High Torque: GAM Mechanical Drive Trains are designed to deliver high torque even at low speeds. This makes them ideal for heavy-duty machinery that requires a lot of power to operate.

-

Durable: GAM Mechanical Drive Trains are made of high-quality materials that are designed to withstand the wear and tear of heavy-duty operation. This means that they last longer and are less likely to fail, which translates to reduced downtime and increased productivity.

Optimizing the Design of a Precision Mechanical Drive System

When designing a precision mechanical drive system for a servo motion control system, there are many considerations beyond torque and backlash requirements. By carefully considering dimensional compatibility, component compatibility, machine performance specifications, the total cost of ownership, and the advantages of single sourcing, designers can optimize the performance and reliability of the system while minimizing costs. By taking these considerations into account, designers can ensure that the mechanical drive system is an asset to the overall system, rather than a bottleneck or a source of problems.

Dimensional Considerations

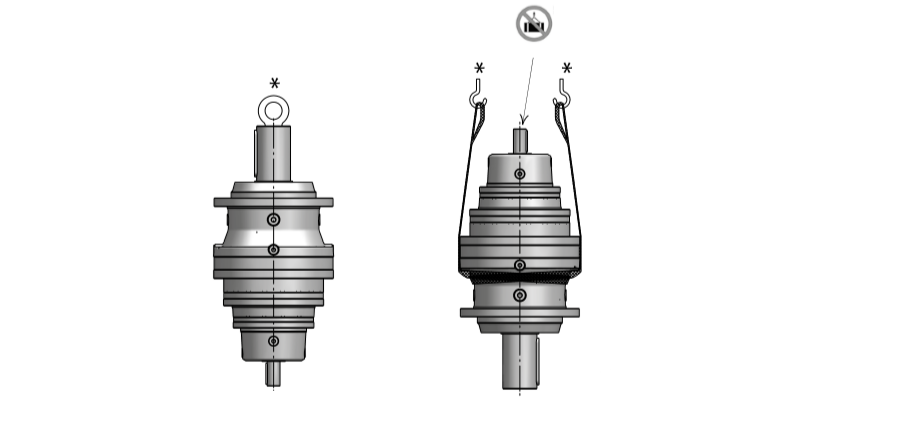

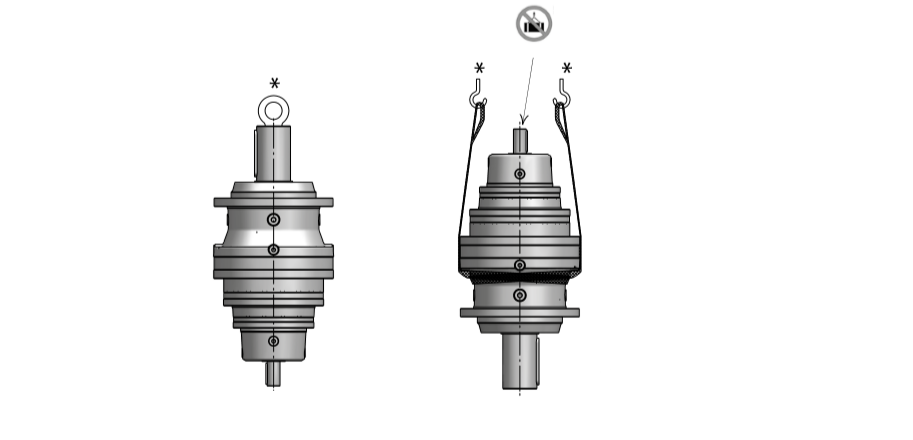

One of the key considerations when designing a mechanical drive system is dimensional compatibility. This means ensuring that all the components in the drive train, including gears, couplings, and motors, are designed to work together seamlessly. When the components are not compatible, it can lead to performance issues, such as excessive noise and vibration, reduced efficiency, and even component failure.

To avoid these issues, designers should carefully consider the dimensional compatibility of all the components in the system. This includes checking the fit of the gears, the alignment of the couplings, and the suitability of the motor for the application.

Component Compatibility

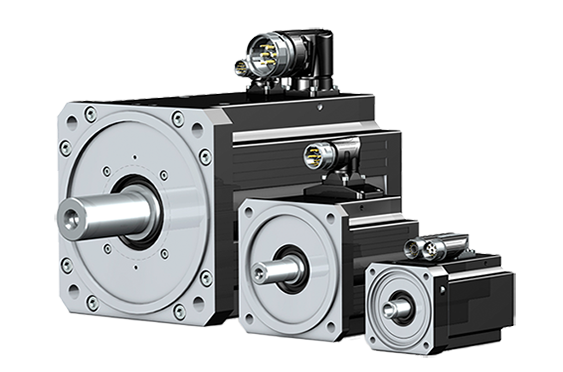

Another important consideration is component compatibility. This means selecting components that are specifically designed to work together, rather than mixing and matching components from different manufacturers. While this may seem like an unnecessary limitation, it can actually improve the overall performance and reliability of the system.

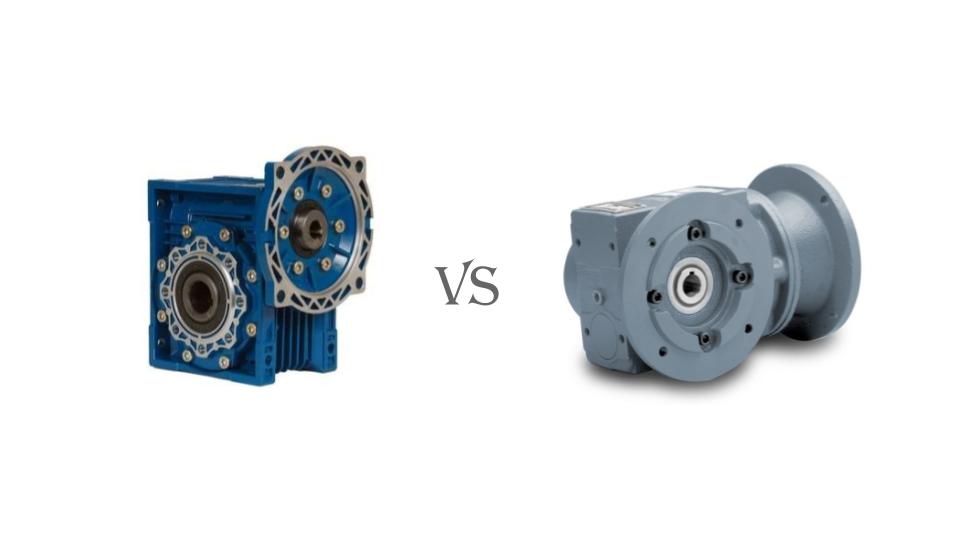

For example, The use of an elastomer coupling at the output of a high-precision gearbox results in zero backlash but reduces the torsional stiffness of the system, which counteracts the benefits of the high-precision gearbox. Therefore, a bellows coupling would be a more suitable option.

Meeting Machine Performance Specifications

Precision in motion control applications using servo motors requires measuring various parameters, including backlash, torsional stiffness, and lost motion. Backlash refers to the play or clearance in the gears causing output shaft movement relative to the fixed input shaft. Torsional stiffness, on the other hand, measures the gearbox or coupling's rigidity to withstand external forces' twisting angle. Lost motion, a combination of backlash and torsional stiffness, varies depending on the applied torque. The precision of each component in a system can add up to the overall precision, and improving or eliminating a component can reduce the stack-up tolerance.

Total Cost of Ownership

While optimizing the performance of a mechanical drive system is important, it is equally important to consider the total cost of ownership. This includes not only the initial cost of the components but also the cost of maintenance, repairs, and replacement over the life of the system.

To minimize the total cost of ownership, designers should consider factors such as component reliability, ease of maintenance, and availability of spare parts. By selecting components that are reliable and easy to maintain, the system can operate at maximum efficiency with minimal downtime and repair costs.

Single Sourcing

Single sourcing means selecting components from a single manufacturer rather than sourcing components from multiple manufacturers. Single sourcing for mechanical drive components in motion control systems has several advantages. By having one supplier take ownership of the design, the components are selected and optimized to work together, resulting in an improved overall design. This can also lead to sub-assemblies being supplied, saving time during final assembly. Additionally, single sourcing can reduce the number of purchase orders and freight costs, and prevent issues related to failure and design errors.

In conclusion, designing a mechanical drive train in a servo motion control system involves more than simply selecting components that meet torque and backlash requirements. By considering dimensional considerations, component compatibility, machine performance specifications, the total cost of ownership, and the advantages of single sourcing, it's possible to design a more effective and efficient system that delivers optimal performance over the long term.

HVH Industrial Solutions is an authorized distributor of GAM. We work closely with their engineering team to provide superior customer service and engineering support.

If you have any questions, write us via live chat, call, or send us a quote request. The HVH team is always ready to help you.

You can also check our blog article GAM Custom Gearboxes.