Gear Couplings

HVH Industrial works with many industry-leading manufacturers of gear couplings. We have extensive resources to offer you the gear coupling that meets your requirements and, at the same time, has the best price and lead time. The gear couplings we offer meet the highest quality standards.

Top gear coupling manufacturers we work with:

- Ringfeder Power Transmission

- Ameridrives

- Rota Free / Compomac

- System Components

- Fachini

- RINGSPANN

- FLENDER

- MALMEDIE

- Guardian Couplings

- KRT Systems

- Rexnord Falk

A gear coupling is a flexible coupling intended to connect two shafts at their ends to transmit power and transfer rotational movement from one shaft to another.

Benefits of using Gear Couplings

-

High torque density

-

Three types of misalignment (angular, parallel, axial)

-

High torque at high speeds

Torsionally rigid and low-backlash gear couplings are made of high-strength steel. They are proving themselves worldwide in all industrial sectors where extraordinarily high torques must be transmitted from shaft to shaft. These include particularly heavy-duty applications, e.g., in the direct drive of conveyor systems, mixers, rolling mills, or roller tables. As flexible shaft connections, gear couplings transmit the torque positively using hubs with crowned teeth, which are constantly in mesh with the straight-toothed tooth sleeves. They are characterized by extremely high power densities and, depending on the coupling variant, are also suitable for the adequate compensation of axial, radial, and angular shaft misalignments.

Lubrication Importance

The couplings require periodic lubrication every 1-2 years, depending on duty and type of lubrication. If properly maintained (with good lubrication and proper alignment), the coupling has a service life of 3-5 years and, in many cases, 5-10 years.

Some have a sleeve made of plastic (nylon, high molecular plastic); these don’t require lubrication. They have much lower torque capacity than steel-made couplings and are used mainly on small pumps.

Depending on application requirements, we can help you determine whether you need a keyway, spline, or shrink disc connection. The HVH team works closely with experts in tooth design, material and lube selection, and manufacturing techniques, ready to serve you.

If you have any questions, write us via live chat (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Filter by Title

Filter by Price

Filter by Type

Shaft Couplings(8)

Filter by Brands

System Components (8)

8 Items Found

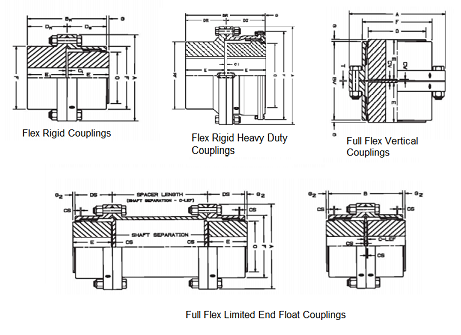

MPN: S FF

Powertork Sleeve Type Full Flex Couplings are m<... Read more

Availability:

MPN: S FR

Powertork Rigid Sleeve and Shaft Couplings are produced from highly qualified stainless steel utilized in wide vari... Read more

Availability:

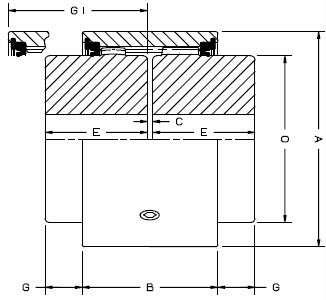

MPN: FF EB

Flange type of full flex is a srong rugged gear coupling applied for a wide range of industrial power transmission ... Read more

Availability:

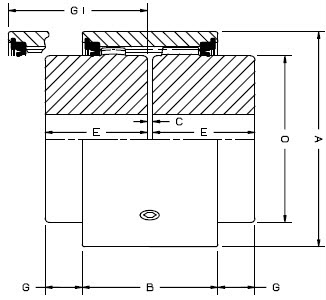

MPN: FFHD EB

Flange type of full flex heavy duty couplings are srong rugged gear couplings utilized for a wide range o... Read more

Availability:

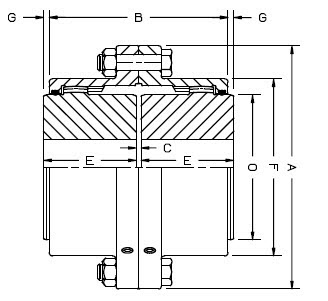

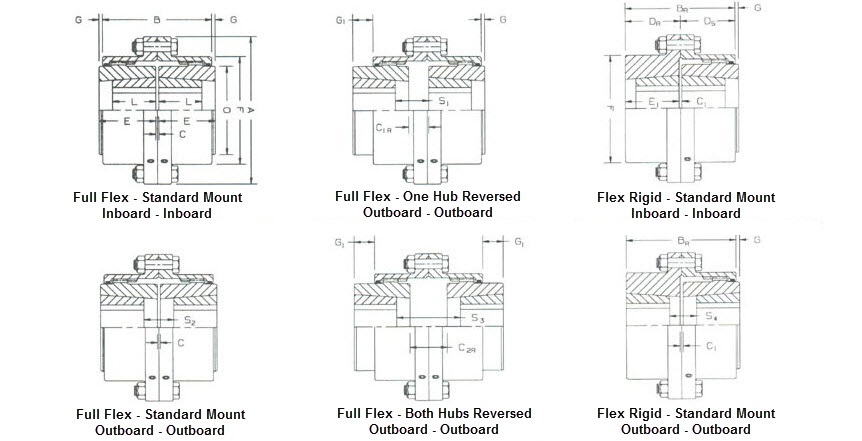

MPN: FF EB / FR EB

Flex Rigid and FF vertical (F1-F7), FR heavy duty (F8-F18) and FF limited float (F1-F4) couplings are srong ru... Read more

Availability:

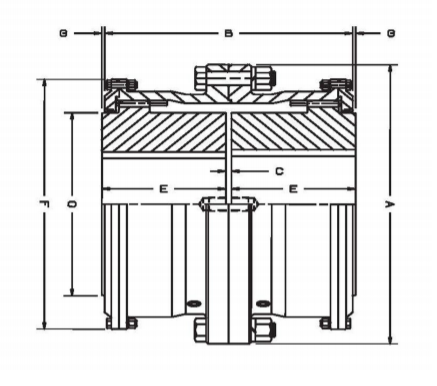

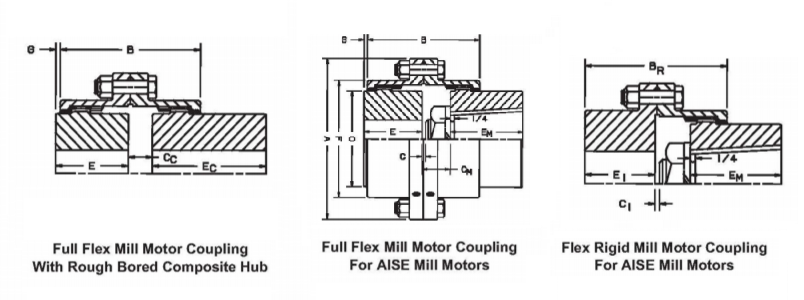

MPN: FFMM RSB EB

Mill Motor couplings are stainless steel made of gear couplings utilized for a wide range of industrial p... Read more

Availability:

MPN: FF TL II EB

Couplings intended for Taper-Lock Bushings are srong rugged gear couplings applied for a wide range of industr... Read more

Availability:

MPN: CCF

F series of cutout couplings used on dual drives have an auxiliary prime ... Read more

Availability: