Ameridrives Disc and Diaphragm Couplings: Characteristics and Benefits

In the world of high-performance machinery, disc, and diaphragm shaft couplings play a crucial role in transmitting torque and accommodating misalignment between equipment shafts. These non-lubricated couplings rely on the flexure of metallic membranes to handle angular and axial misalignment, ensuring efficient operation and longevity of the machinery. In this article, we will discuss the two principal types of couplings, their characteristics, benefits, and considerations, with a specific focus on Ameriflex diaphragm coupling.

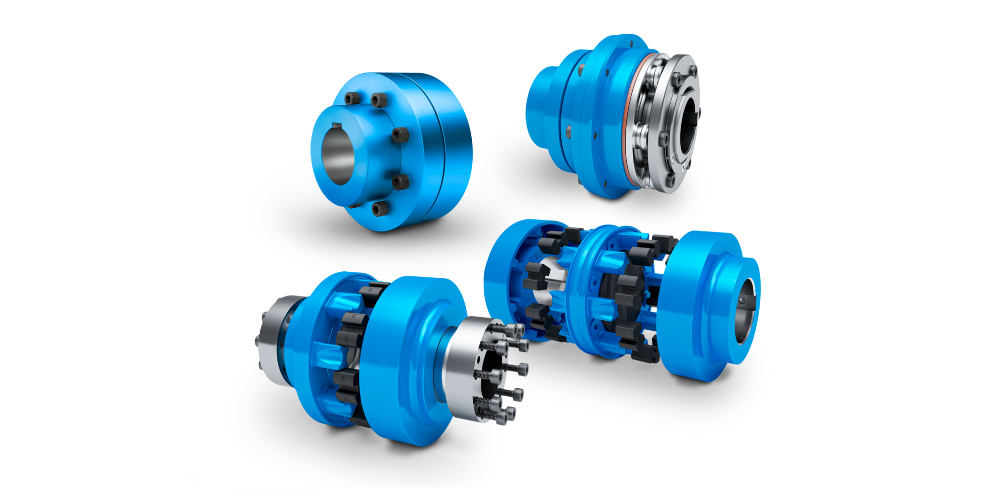

Disc Couplings

Disc couplings utilize the flexure of metallic discs to transmit torque. These couplings consist of thin, metallic rings stacked together, typically in a circular, hex, or scalloped shape. The driving bolts pull the driven bolts, with the disc material at a constant bolt circle, enabling torque transmission. To maintain the integrity of the coupling, the discs are clamped together with washers using bolts attached alternately to the driving and driven flanges.

Disc Couplings Misalignment

While disc couplings offer a long service life, they are not infinite-life couplings. During misalignment, the flexing of the discs can lead to surface rubbing between adjacent discs, resulting in fretting and wear. This fretting can create a favorable environment for corrosion to attack the disc material, leading to corrosion fatigue and potential fatigue failure. However, proper design considerations, such as disc shape (e.g., scalloping) and thickness, can help mitigate fretting corrosion to some extent.

To enhance the finite coupling life of disc couplings, some manufacturers apply coatings to the discs. However, studies have shown that most coatings have a negative impact on the endurance strength of the base material. Therefore, it becomes crucial to carefully evaluate the impact of coatings on the overall performance and durability of the coupling.

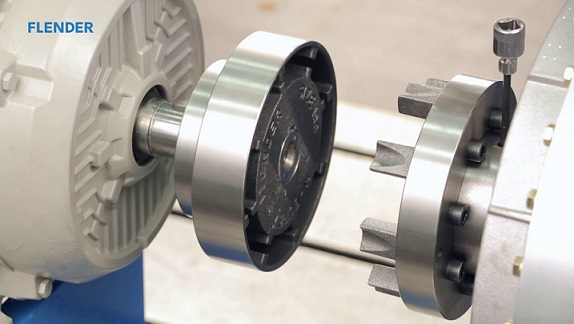

Installation and Service Life of Disc Couplings

Moreover, the selection and proper installation of disc coupling bolts play a critical role. The inherent design of disc couplings requires the bolts to transfer torque through shear and bending. The highest bolt stresses occur in bending, which differentiates disc couplings from diaphragm couplings, where torque subjects the bolts predominantly to shear stresses. By ensuring the appropriate tension of the disc coupling bolts, the bending stress can be reduced to acceptable levels, thus influencing the fretting and corrosion fatigue characteristics at the washer interface.

It is worth noting that the service life of identical disc coupling designs can vary among different applications and sites. Factors such as actual misalignment, preload in the bolts, and specific environmental conditions can influence the performance and durability of disc couplings. Adhering to the manufacturer's recommended bolt-tightening torque and minimizing misalignment can help maximize the service life of disc couplings.

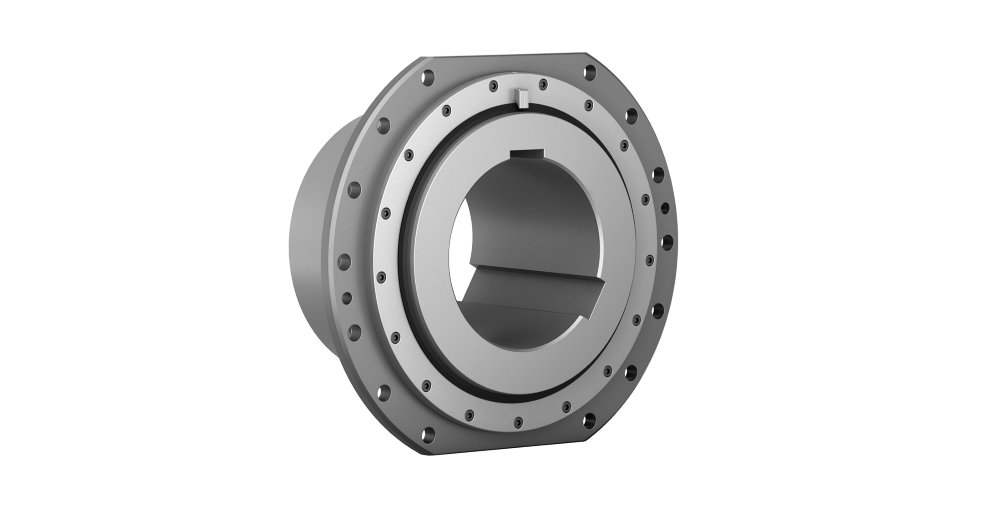

Diaphragm Couplings

Diaphragm couplings, the other principal type of non-lubricated couplings, transmit torque radially from the outside diameter of a drive flange through one or more metallic plates to an attachment at the inside diameter. The diaphragms can have constant or tapered thickness and may be flat, convoluted, or spoked. The outside diameter of the diaphragm is typically clamped by bolts, while the inside diameter is secured through electron beam welds, splines, or bolts.

Diaphragm couplings offer distinct advantages over disc couplings in terms of their design and performance. The diaphragms in diaphragm couplings are separated at the inside and outside diameters, thereby preventing fretting corrosion resulting from angular and axial misalignment. This separation significantly reduces the likelihood of surface rubbing between flexing areas of multiple membrane couplings.

In terms of material selection, diaphragm couplings commonly employ austenitic stainless steels, such as 301 full hard stainless steel, as standard disc materials. However, in corrosive environments where stress corrosion cracking can occur, alternate materials like Inconel, known for their high resistance to stress corrosion, are often preferred.

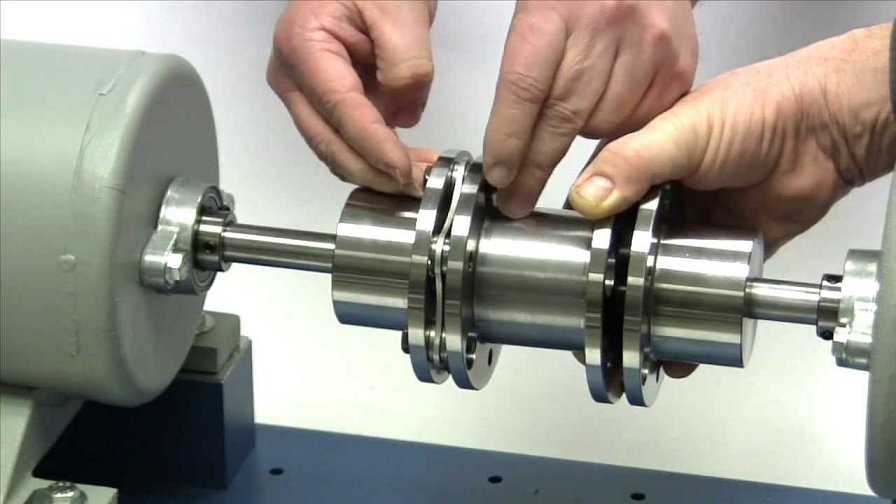

Ameriflex Diaphragm Couplings

The design of Ameriflex diaphragm couplings takes into account the principles of infinite life engineering fatigue analysis. The multiple, convoluted diaphragm flex areas in the Ameriflex coupling are separated, eliminating the risk of fretting corrosion or wear affecting the coupling's raw material endurance limit. Additionally, each diaphragm undergoes shot peening, a process that imparts compressive stress on both sides of the diaphragm. This compressive stress helps prevent stress corrosion cracking in those areas.

The Ameriflex coupling design allows for the calculation of safety factors using various fatigue failure theories, such as the Goodman, modified Goodman, or Constant Life methods. By accurately assessing the stresses using finite element analysis and strain gauge testing, Ameridrives can provide couplings with true infinite life design, with diaphragm packs operating for over twenty years. This reliability translates into predictable maintenance and inspection intervals, regardless of the coupling's misalignment, environmental conditions, or service duration.

Failure Comparison: Disc Coupling vs. Ameriflex Diaphragm Coupling

In the event of failure, disc couplings and diaphragm couplings differ in their effects on the system. If a failure occurs in a disc coupling, whether due to fatigue from fretting corrosion or ultimate failure resulting from peak torque overload, the driving flange bolts will continue to load the driven flange bolts, driving the equipment. This condition can cause significant damage to the adjoining equipment and lead to high vibrations. Adequate vibration monitoring and overspeed trip devices are crucial to prevent further damage.

In contrast, when an Ameriflex diaphragm coupling experiences excessive misalignment that initiates a fatigue failure, the crack will gradually propagate due to the separation of the diaphragm flex areas. Eventually, as each diaphragm fails, the remaining diaphragms will shear at their inside diameter due to excessive torque. Importantly, regardless of the cause of failure, whether fatigue or ultimate failure, the diaphragm's inside diameter will shear from the spacer or spool, resulting in an instantaneous loss of load and triggering a standard turbomachinery overspeed trip. The anti-flail guards in the Ameriflex coupling contain the center section for safety and to protect the adjoining equipment.

Coupling Selection Considerations

When selecting a coupling, several factors should be taken into consideration. For disc couplings, the service life is finite and significantly affected by equipment misalignment, disc configuration, disc coatings, bolt preload, and environmental conditions. It is crucial to carefully assess these factors to ensure optimal coupling performance and durability.

On the other hand, Ameriflex diaphragm couplings offer a true infinite life design with numerous advantages. The separation of diaphragm flex areas prevents fretting corrosion, and the diaphragms' raw material endurance limit remains uncompromised by wear, corrosion, or coatings. With built-in redundancy and fail-safe features, Ameriflex diaphragm couplings provide a high level of reliability and safety.

Conclusion

When it comes to diaphragm couplings, Ameridrives Couplings' Ameriflex diaphragm coupling stands out for its infinite life design, separation of flex areas, and fail-safe features. By selecting the appropriate coupling and adhering to recommended maintenance practices, industries relying on high-performance turbomachinery can ensure reliable and efficient operation while minimizing the risks associated with misalignment, fatigue, and failure.

HVH Industrial Solutions is an authorized distributor of Ameridrives and we offer a wide range of their products. We work closely with their engineering team to provide superior customer service and engineering support.

If you have any questions, write to us via live chat or call or send us a quote request. The HVH team is always ready to help you.