The Power and Precision of Flender's N-EUPEX Couplings

For industrial machinery, where consistent power transmission is essential, Flender's N-EUPEX Couplings stand as a standard of reliability and cost-effectiveness. Widely used across diverse applications, such as pumps for waterworks, the N-EUPEX coupling is one of the most used couplings globally. In this article, we will dive into the workings of the N-EUPEX coupling, exploring its features, applications, and the century-old engineering brilliance behind its design.

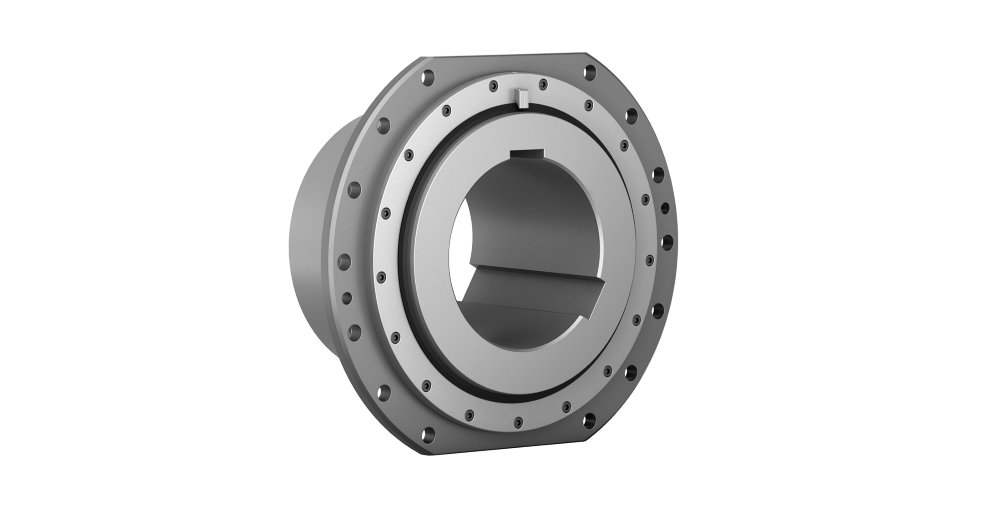

N-EUPEX's Compact Flexible Design

The N-EUPEX is a flexible coupling that effortlessly absorbs given mechanical loads to shield the motor, gear unit, and working machine. It is essential, particularly during critical operational phases—start-up, stopping, or gear transitions—where N-EUPEX's damping properties play a pivotal role in reducing peak loads, thereby safeguarding the entire system from potential damage.

A standout feature of the N-EUPEX is its compact design, a strategic element that not only conserves valuable installation space but also translates to lower costs for brackets and plant design. This attribute proves particularly advantageous in sectors like waterworks pumps, characterized by standardized dimensions and a demand for greater system stability.

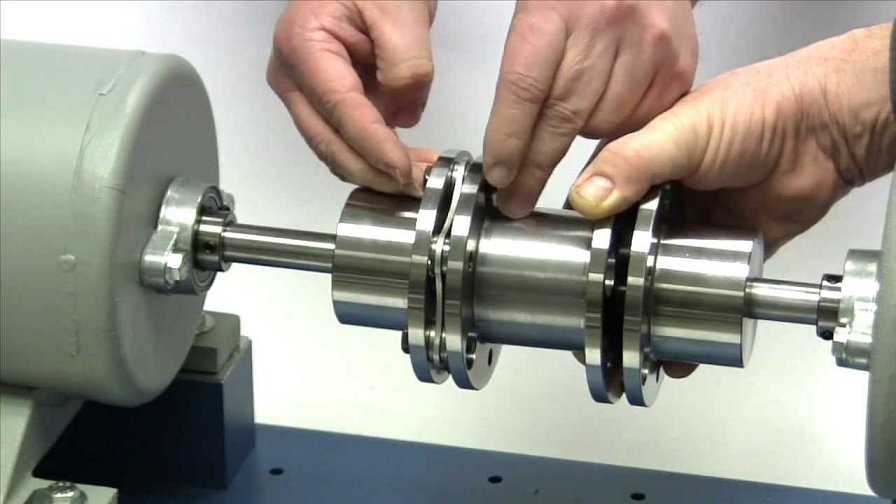

Compensation for Shaft Misalignment

In practical production environments, achieving perfect shaft alignment is a rarity. The N-EUPEX rises to this challenge by compensating for three types of misalignment: axial offset, angular offset, and radial offset. This adaptability ensures the coupling's effectiveness in a myriad of scenarios, contributing to its widespread usage across diverse applications.

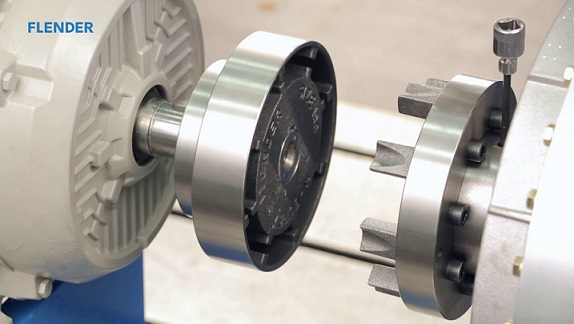

A Century of Innovation

The roots of the N-EUPEX concept trace back a century when Flender engineers embarked on a mission to develop an exceptionally cost-effective universal coupling. The result—N-EUPEX—transfers torque through advanced elastomers and flexible coupling assemblies crafted from synthetic rubber. The interlocking connection between pins and counterparts, coupled with an easily installed plug-in assembly, allows N-EUPEX to operate seamlessly in both directions of rotation and reverse, with generous gap dimensions accommodating axial play.

Managing Compression Loads

The N-EUPEX's assemblies primarily endure compression loads, with a unique design that allows the elastomer flexible just enough space to deflect under load during misalignment. In cases of radial shaft misalignment, the interlocking connection between pins and assembly compensates for the offset, showcasing the coupling's ability to handle radial misalignment up to 0.3% measured from the outer diameter without abrasive wear.

Reducing Vibrations and Noise

Crafted from high-quality cast iron, the N-EUPEX coupling components boast a significant graphite content, effectively reducing mechanical vibrations and noise. The precision achieved through a special casting process, producing components with minimal draft and close tolerances, contributes not only to cost-effectiveness but also to the coupling's exceptional precision.

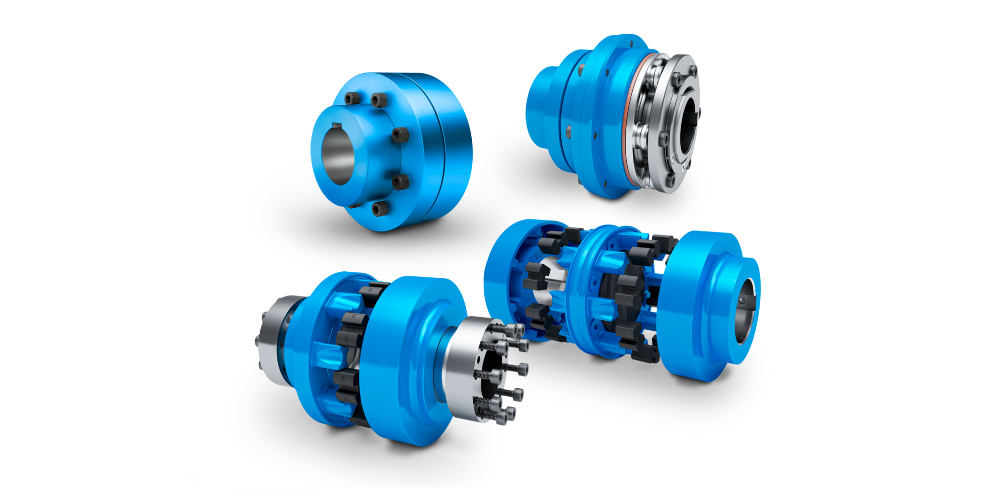

Modularity and Versatility

The N-EUPEX's modular system accommodates both fail-safe and non-fail-safe options, namely N-EUPEX and N-EUPEX-DS, providing users with the flexibility to retrofit or modify at a later time. This standard portfolio not only simplifies logistics and costs but also aligns with the N-EUPEX's core principles of outstanding capabilities and simple functionality.

Conclusion

For decades, the N-EUPEX coupling has maintained its unwavering success, driven by a remarkable price-performance ratio. As a testament to Flender's commitment to innovation, this coupling continues to be a preferred choice, offering reliable and cost-effective power transmission solutions across diverse applications worldwide.

HVH Industrial Solutions is an authorized distributor of Flender. We work closely with their engineering team to provide superior customer service and engineering support.

If you have any questions, write to us via live chat or call or send us a quote request. The HVH team is always ready to help you.